Tailored to your requirements – corrugator lines from BHS Corrugated

As an leading company, BHS Corrugated offers a wide range of individual machines. Our carefully assembled portfolio of corrugator lines is optimally adapted to meet the needs of every customer. From affordable corrugator lines for modest local markets to highly flexible lines – equipped with a plethora of automation features – to solutions that ensure maximum productivity for the long term. And every corrugator from BHS Corrugated comes with outstanding quality and reliability guaranteed. So, invest in the future of your corrugator today, and let us make your operations more profitable than ever.

Get to know our different corrugator lines in detail!

WIDTH Line

WIDTH Line

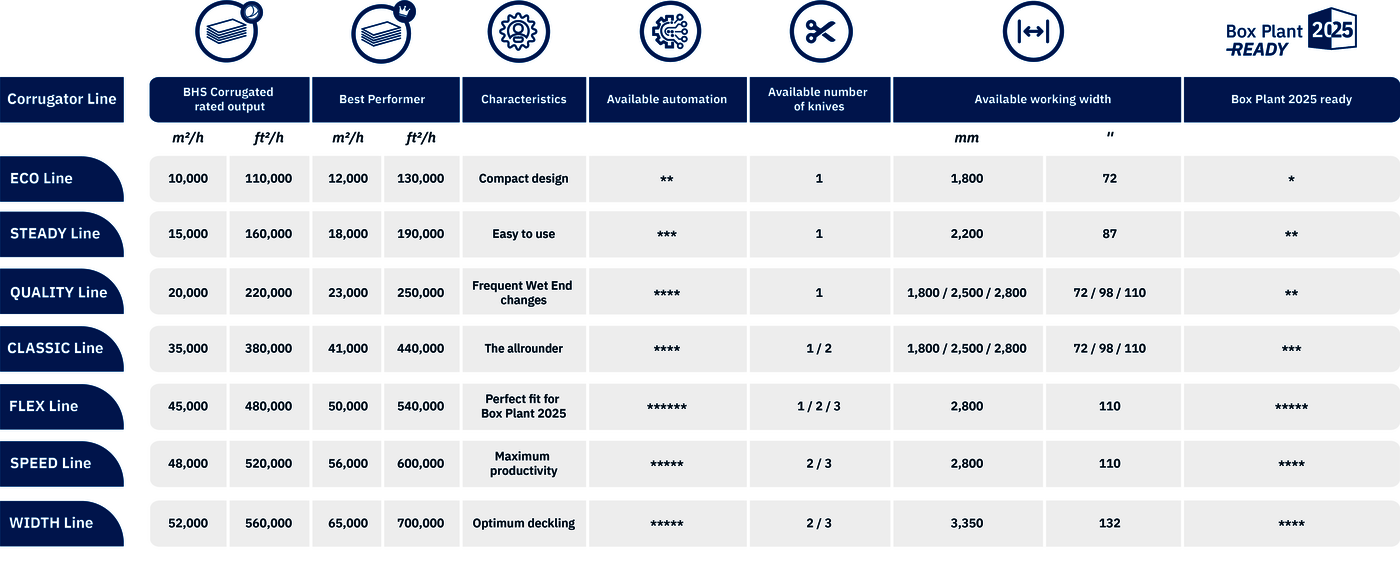

WIDTH Line: extra-wide solutions for mega-plants

The WIDTH Line is a complete corrugator from BHS Corrugated. Amongst others, it is also interesting for paper manufacturers who want to add corrugated board production to their value chain. With their extra-large working width of 3,350 mm, these corrugator lines are extremely cost-effective. Compared with corrugators of narrower working widths, they achieve lower trim loss and reduce logistics expenses within the factory. Even if trim is reduced by just a few percent, a WIDTH Line from BHS Corrugated will quickly pay for itself.

SPEED Line

SPEED Line

SPEED Line: high-volume solutions for transregional markets

To dependably supply large orders while keeping unit costs to a minimum, you need a high-speed corrugator line that is highly reliable and efficient. The SPEED Line from BHS Corrugated features systems that are automated end-to-end, enabling you to achieve production volumes of up to 56,000 m²/hour. You also get maximum machine availability, fast service and cost-efficient machine configurations.

FLEX Line

FLEX Line

FLEX Line: ready for a new era

The FLEX Line offers the full potential to make the Box Plant 2025 strategy real. And that’s for good reasons. The FLEX Line is the most automated and end-to-end digital corrugator line from BHS Corrugated – ready for smooth integration of Jetliner® digital print and autonomous iMotion intralogistics.

Use intelligent automation technology for optimal operation, high productivity, excellent quality of your products – and minimize your carbon footprint.

The FLEX Line keeps your production always adaptable – whether it's a broad mix of orders, new market trends or rapid digital transformation. You can process all customer orders with outstanding quality – using flutes from G to AAA, corrugated board grammages from 150g/m² to 3,000g/m², a wide variety of papers from 40g/m² to 440g/m²...

With the FLEX Line, the Box Plant 2025 becomes a reality!

CLASSIC Line

CLASSIC Line

CLASSIC Line: flexible for local markets

Optimal local market coverage with a wide variety of packaging solutions including everything from microflutes to small orders – the CLASSIC Line from BHS Corrugated stands for reliable corrugator lines with cutting-edge, intuitive technology. CLASSIC gives you the flexibility you need to meet any customer’s requirements.

QUALITY Line

QUALITY Line

QUALITY Line: reliable solutions for single-knife markets

Would you like to excel with top quality and high output volumes, all without compromising on availability and service life? What your operations needs is a single-knife Dry End. The QUALITY Line from BHS Corrugated was created precisely for this purpose.

STEADY Line

STEADY Line

STEADY Line: maintain constant speed with frequent changeovers

The STEADY Line from BHS Corrugated was created for customers who receive a lot of very short orders, requiring them to change formats frequently and for whom moderate output volumes are sufficient. This corrugator line is designed to maintain constant speed as you change formats and grades. The result is thoroughly simple operation and consistently high-quality corrugated board.

ECO Line

ECO Line

ECO Line: a future-proof product for emergent markets

Are you looking to invest in a potential market? Or maybe you need a high-quality solution for packaging your own products? The ECO Line from BHS Corrugated meets the needs of manufacturers with a monthly output of 2,500 to 3,000 tons and performs even under challenging production conditions.

“One size fits all” – still the right approach today?

Until recent years, corrugated board manufacturers had just two options to choose from. Either they go with a ready-made corrugator layout barely able to accommodate local or regional market requirements. Or they opt for the time-consuming route of assembling their own tailored corrugator from individual components. End-to-end corrugator lines from BHS Corrugated give you the best of both worlds. They are perfectly adapted to a variety of market requirements – particularly with regard to differing production yield and automation needs. At the same time, they also offer a wide assortment of individual options, giving you a corrugator line that is practically unique – all with the time-saving advantages of a tried and tested solution.

Trainings

Your direct way to the corrugator

Contact

BHS Corrugated

Maschinen- und Anlagenbau GmbH

Paul-Engel-Straße 1

92729 Weiherhammer

Hotlines

24-hour Emergency Hotline

+49 9605-919-191

Spare Parts Hotline

+49 9605-919-291 spareparts@bhs-world.com

When you click the play button, content from the YouTube video platform is loaded. Cookies can be saved in the process.

When you click the play button, content from the YouTube video platform is loaded. Cookies can be saved in the process.New video about the Cassette Facer CF-A of BHS Corrugated

How does the Cassette Facer CF-A interact with the FLEX Line?

Based on the industry proven design of the Modul Facer®, the new Cassette Facer CF-A…

An Innovative Start to the Year: BHS Corrugated Introduces the FLEX Line!

Rarely does one experience the beginning of a new era in their own industry. At BHS Corrugated, we have made it our mission to create such…

BHS Corrugated receives HxGN Customer Innovation Award 2023 for iCorr® Maintenance and Operations System (MOS)

We are pleased to announce that our cloud-based maintenance solution, iCorr® MOS (Maintenance and Operations System), has been awarded the HxGN…

Belt meets cassette: The new Cassette Facer CF-A from BHS Corrugated

With the launch of the Cassette Facer CF-A, BHS Corrugated has added another model to its range of single-sided machines. Positioned between the Econo…