BHS Corrugated's first sustainability report now available online!

The world around us is changing at a breathtaking pace. The increasing warming of our planet, the changing climate conditions and their tangible…

BHS Corrugated supports local sports clubs with a generous donation

BHS Corrugated supports the Förderverein Fußball Weiherhammer 1998 e.V. and FC Kaltenbrunn with a generous donation for the renovation of their sports…

Two years of war: BHS Corrugated remains firmly on Ukraine's side

We all remember February 24, 2022 - exactly two years since the war raged in Ukraine. Since then, BHS Corrugated has been supporting the affected…

An Innovative Start to the Year: BHS Corrugated Introduces the FLEX Line!

Rarely does one experience the beginning of a new era in their own industry. At BHS Corrugated, we have made it our mission to create such…

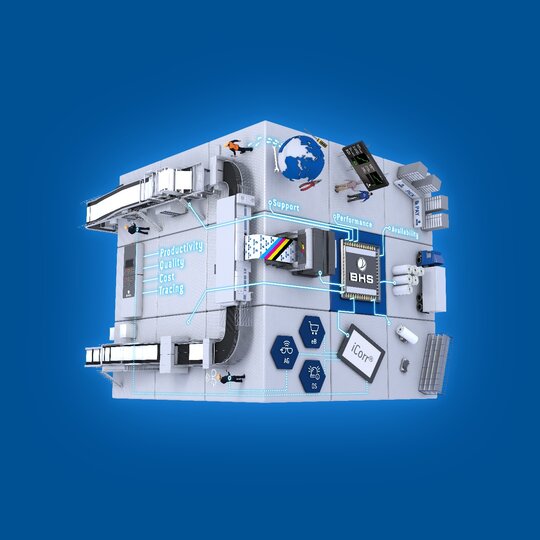

BHS Corrugated receives HxGN Customer Innovation Award 2023 for iCorr® Maintenance and Operations System (MOS)

We are pleased to announce that our cloud-based maintenance solution, iCorr® MOS (Maintenance and Operations System), has been awarded the HxGN…

When you click the play button, content from the YouTube video platform is loaded. Cookies can be saved in the process.

When you click the play button, content from the YouTube video platform is loaded. Cookies can be saved in the process.Experience the drone show about the 30th anniversary of BHS Corrugated!

In July 2023, the employees celebrated the 30th anniversary of BHS Corrugated Maschinen- und Anlagenbau GmbH together.

The highlight of the evening…

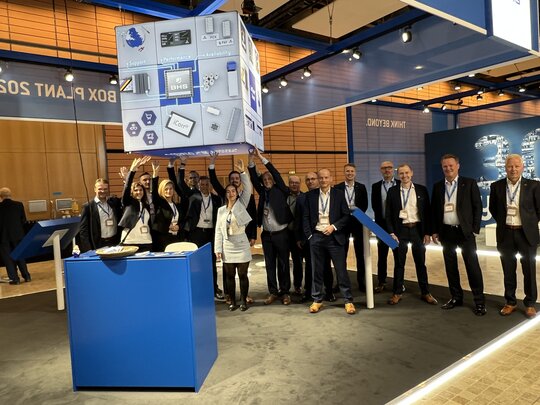

A look back: BHS Corrugated at the FEFCO 2023

Every two years, FEFCO (European Federation of Corrugated Board Manufacturers) organizes the FEFCO Technical Seminar in a major European city.

From…

BHS Corrugated receives official seal of approval for research and development

In 2022, the research and development expenses of BHS Corrugated Maschinen- und Anlagenbau GmbH amounted to EUR 17.7 million, which corresponds to an…

BHS Corrugated Reviews the Last 30 Years with the Reading of 'Wellengang'

An evening full of insights into the development of a global player: Approximately 100 guests embarked on a journey through the last 30 years of the…

Belt meets cassette: The new Cassette Facer CF-A from BHS Corrugated

With the launch of the Cassette Facer CF-A, BHS Corrugated has added another model to its range of single-sided machines. Positioned between the Econo…

Visit BHS Corrugated at FEFCO 2023!

Visit BHS Corrugated's booth at the FEFCO Technical Seminar for an exclusive look at the latest technologies of the Box Plant 2025. This holistic and…