Preheater: Optimal heat transfer

Whether you choose an external Preheater with a Single Facer or a Triplex Preheater: With Preheaters from BHS Corrugated, you reach the desired process temperatures and required tension in the papers with equal reliability. This results in optimal bonding of the individual paper webs, as well as ideal flatness of the final corrugated board!

The features of our Preheater

Steam energy

Steam energy

Minimize process energy consumption

The production of flawless corrugated board always goes hand-in-hand with maximally efficient use of steam energy. Efficient control and maintenance of the selected process temperatures also always means: Use as little process energy as possible – as much as absolutely necessary!

Control

Control

Optionally speed- or temperature-controlled

By default, the Preheater drums have a diameter of 1,100 mm. They are designed for paper speeds up to 600 m/min. The drums ensure the best possible heat transfer. The hinged tandem wrap rolls allow you to control the paper wrapping operation (with automatically regulated cylinder contact) according to either speed or temperature. The integrated pendular rolls balance out the web tension variances and potential fluctuations in the temperature transmissions.

Advantages

Advantages

An overview

- Chromed cylinders: Not only do these ensure optimal heat transfer, they also guarantee longer service life

- Throughout the entire process, the electronic control system offers consistent, optimally tared web tension for all speed settings

- Optimal utilization of the cylinder surface thanks to a combination of tandem wrap rolls and chain wheel actuation

- All machines are safety-tested in the application areas

- Threading guide facilitates web thread-up

- Various diameters for the best possible application in each case

Machine safety

Machine safety

The highest standards

Adherence to high standards and compliance with strict regulations are crucial to ensure the safety of users. The quality of the machines also contributes significantly to this. Our products meet these requirements and we do everything we can to ensure that they meet the highest standards. Your safety and satisfaction are our top priority.

Trainings

Your direct way to the corrugator

Contact

BHS Corrugated

Maschinen- und Anlagenbau GmbH

Paul-Engel-Straße 1

92729 Weiherhammer

Hotlines

24-hour Emergency Hotline

+49 9605-919-191

Spare Parts Hotline

+49 9605-919-291 spareparts@bhs-world.com

When you click the play button, content from the YouTube video platform is loaded. Cookies can be saved in the process.

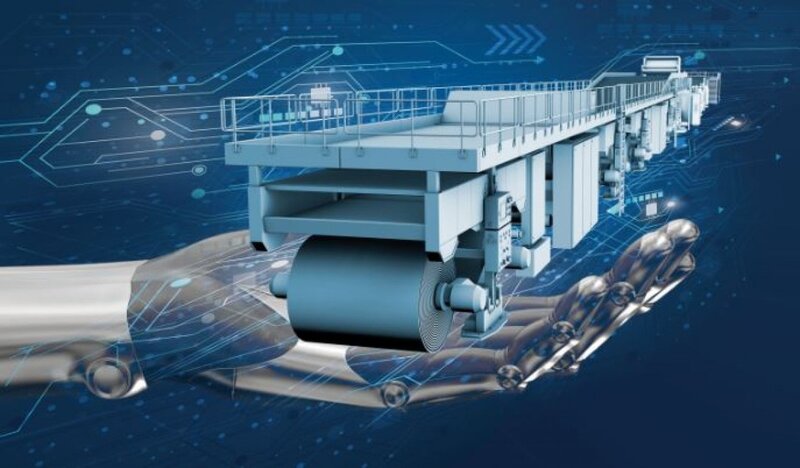

When you click the play button, content from the YouTube video platform is loaded. Cookies can be saved in the process.Corrugator SPEED Line: high-volume solutions for transregional markets

The SPEED Line from BHS Corrugated features systems that are automated end-to-end, enabling you to achieve production volumes of up to 56,000 m²/hour.…

Sustainability unboxed – Discover the new Box Plant 2025 Season of BHS Corrugated!

With its high recycling rates, the corrugated industry is a pioneer of a modern circular economy. However, sustainable action is not limited to the…

When you click the play button, content from the YouTube video platform is loaded. Cookies can be saved in the process.

When you click the play button, content from the YouTube video platform is loaded. Cookies can be saved in the process.Discover the corrugator WIDTH Line from BHS Corrugated!

The WIDTH Line is a complete corrugator from BHS Corrugated. Amongst others, it is also interesting for paper manufacturers who want to add corrugated…

When you click the play button, content from the YouTube video platform is loaded. Cookies can be saved in the process.

When you click the play button, content from the YouTube video platform is loaded. Cookies can be saved in the process.New video about the Cassette Facer CF-A of BHS Corrugated

How does the Cassette Facer CF-A interact with the FLEX Line?

Based on the industry proven design of the Modul Facer®, the new Cassette Facer CF-A…