Steam Systems: reduce energy losses to a minimum

With rising electricity costs and stricter environmental standards, making efficient use of your steam energy has never been more important. BHS Corrugated is the only corrugator manufacturer worldwide to offer a proprietary Steam System. Not only is this system energy-efficient and cost-effective, it is also optimally designed to work with your corrugator. Everything is integrated and conveniently available to you from a single source – so you can look forward to a successful project.

The features at a glance

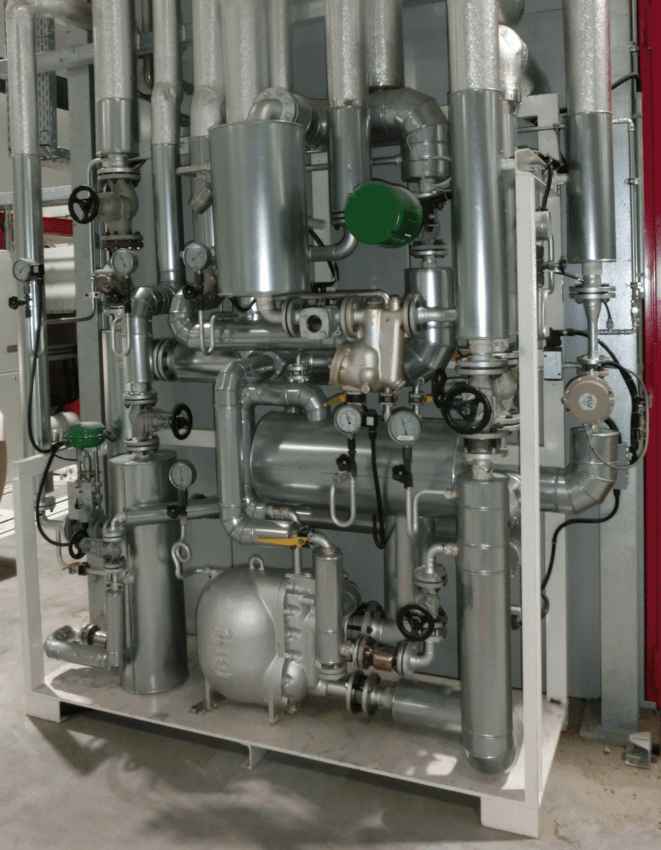

Closed Steam System

Closed Steam System

Less energy loss, more efficiency

When a corrugator is heated using a closed Steam System, energy loss is reduced to an absolute minimum. The principle of “as little as possible, as much as necessary” also applies to steam energy. With carbon footprints still a major topic of concern, it is essential to opt for a state-of-the-art, “intelligent” steam control system for maximum efficiency.

Machine safety

Machine safety

The highest standards

Adherence to high standards and compliance with strict regulations are crucial to ensure the safety of users. The quality of the machines also contributes significantly to this. Our products meet these requirements and we do everything we can to ensure that they meet the highest standards. Your safety and satisfaction are our top priority.

Trainings

Your direct way to the corrugator

Contact

BHS Corrugated

Maschinen- und Anlagenbau GmbH

Paul-Engel-Straße 1

92729 Weiherhammer

Hotlines

24-hour Emergency Hotline

+49 9605-919-191

Spare Parts Hotline

+49 9605-919-291 spareparts@bhs-world.com

When you click the play button, content from the YouTube video platform is loaded. Cookies can be saved in the process.

When you click the play button, content from the YouTube video platform is loaded. Cookies can be saved in the process.Corrugator SPEED Line: high-volume solutions for transregional markets

The SPEED Line from BHS Corrugated features systems that are automated end-to-end, enabling you to achieve production volumes of up to 56,000 m²/hour.…

Sustainability unboxed – Discover the new Box Plant 2025 Season of BHS Corrugated!

With its high recycling rates, the corrugated industry is a pioneer of a modern circular economy. However, sustainable action is not limited to the…

When you click the play button, content from the YouTube video platform is loaded. Cookies can be saved in the process.

When you click the play button, content from the YouTube video platform is loaded. Cookies can be saved in the process.Discover the corrugator WIDTH Line from BHS Corrugated!

The WIDTH Line is a complete corrugator from BHS Corrugated. Amongst others, it is also interesting for paper manufacturers who want to add corrugated…

When you click the play button, content from the YouTube video platform is loaded. Cookies can be saved in the process.

When you click the play button, content from the YouTube video platform is loaded. Cookies can be saved in the process.New video about the Cassette Facer CF-A of BHS Corrugated

How does the Cassette Facer CF-A interact with the FLEX Line?

Based on the industry proven design of the Modul Facer®, the new Cassette Facer CF-A…