A comprehensive package for your individual machines

Looking to upgrade or retrofit your corrugators? Take advantage of our decades of experience and comprehensive know-how. This specialist competence makes itself known right from the technical consulting stage. From there, we support you through all the phases of your project: Planning – assembly and commissioning as well as downstream lifecycle services like maintenance and repair.

When it comes to preparing an action plan for retrofitting, we always start with your short-term and medium-term needs. The resulting projects include everything from minor updates and the replacement of individual units to comprehensive, highly complex retrofitting and corrugator level expansion projects spanning several months or years.

An important point: Anytime we perform retrofitting work at your site, our top priority is making sure that the productivity and efficiency of your overall operation stays as high as ever!

Single – but seldom on its own

Splicer

Splicer

Unobtrusive and always dependable

The BHS Corrugated Splicer guarantees reliable long-term operation. It features TripleControl for constant web tension at speeds of up to 500 m/min, a user-friendly design that makes splicing faster, and service diagnosis – all built to a high standard of machine safety. This machine can also be adapted to your requirements and is available in different configurations.

Reel Stand

Reel Stand

Unobtrusive and hard-working

The faster you can load paper rolls, the less you have to slow down. Reel Stands from BHS Corrugated are designed to unwind paper rolls without any creases. Designed for high stability, these units run smoothly and quietly at speeds up to 750 m/min.

Single Facer

Single Facer

A Single Facer – for a multitude of requirements

Introducing "Econo Facer EF", “Modul Facer® MF” and “Quick Facer QF” – the standard models of our Single Facer. They might be called “Single Facers,” but they are anything but one-dimensional. These machines can produce flute profiles of up to 3,350 mm in width and work with any type of paper. The SoftTouch glue application system provides uninterrupted, direct contact with the corrugating roll for a flawless bond.

Bridge / Bridge Guide / Bridge Brake

Bridge / Bridge Guide / Bridge Brake

The peak of precision

Are you familiar with Webtrol? It is a unique measuring system specially developed by BHS Corrugated which is integrated in the bridge guide to ensure accurate positioning. This is the secret behind the extreme precision of our bridge and bridge guide technologies. The bridge brake is also highly accurate, thanks to an adjustable brake drum. The result is corrugated board with a perfect bond.

Preheater

Preheater

For optimum operating temperatures

Preheaters from BHS Corrugated allow your system to efficiently reach target process temperatures and the required paper tension. Their drums are designed for optimum heat transfer. Paper wrapping can be controlled according to either speed or temperature. Whichever you choose, the result is smooth, constant web tension.

Glue Unit

Glue Unit

For perfectly spread adhesive

The task of a Glue Unit is pretty straightforward: spread precisely the right amount of adhesive over the entire working width of the corrugated board. Use too much glue, and you incur unnecessary costs. Use too little, and your corrugated board will have a less than perfect bond. Glue Unit GU-M from BHS Corrugated utilizes a glue gap adjustment feature to apply precisely the right amount of adhesive – for a high-productivity process and optimum surface quality.

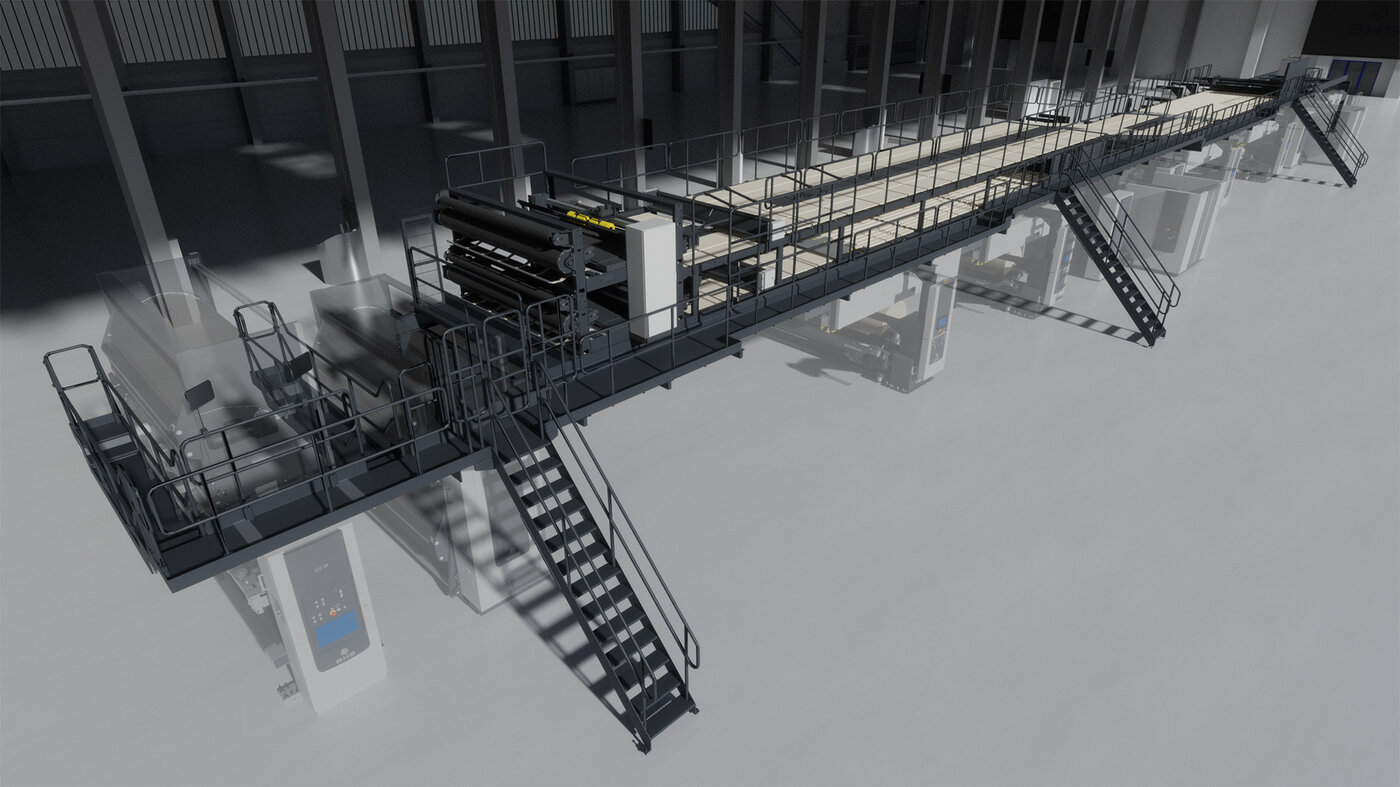

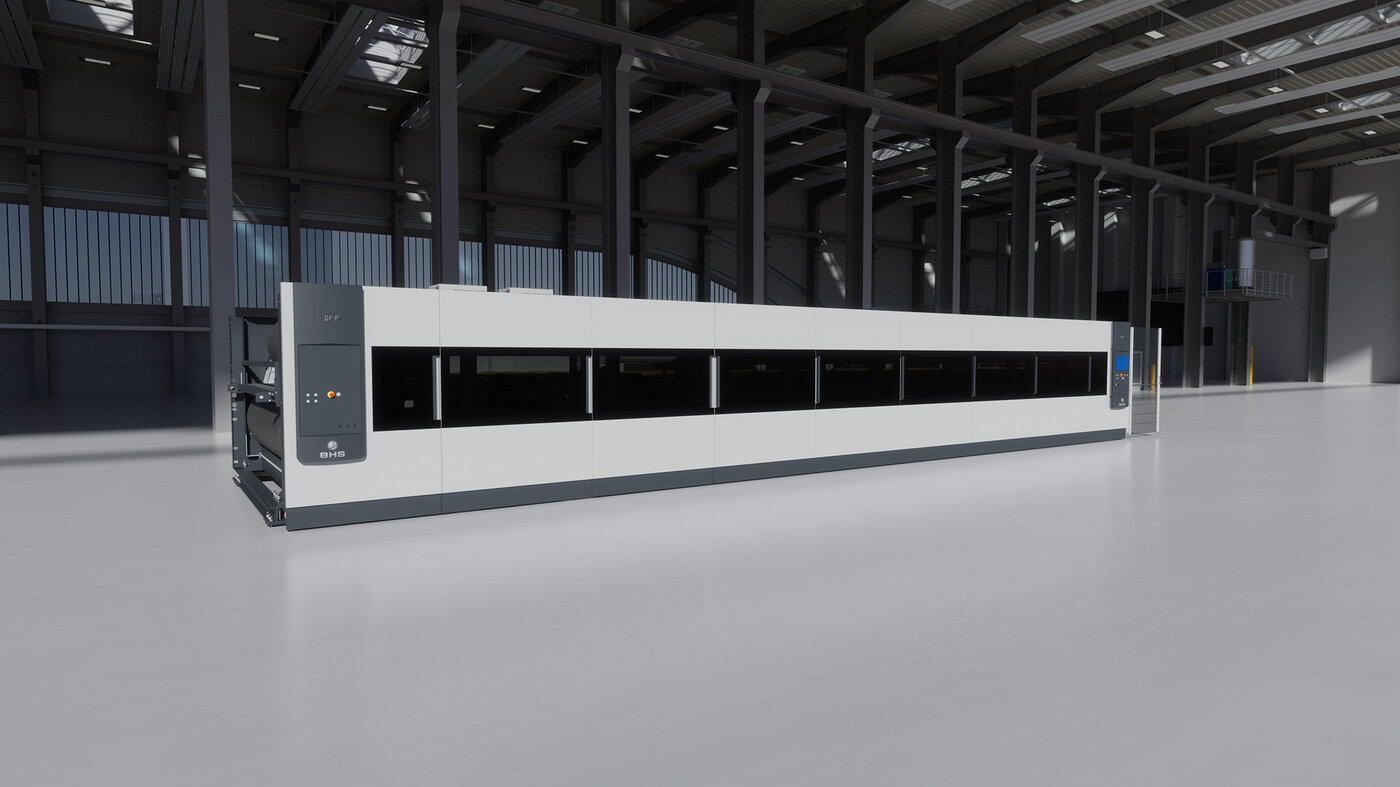

Double Facer

Double Facer

The key to high-efficiency double-fluted board production

The Double Facer from BHS Corrugated is technologically refined down to the smallest detail. With innovative and proven solutions like the Platetrol loading system, the Machine Control Center, pressure shoes, hotplates and Dual Boost web, this system does a flawless job of gluing, drying and transporting your corrugated board webs. Our Double Facer has the high performance capability to reach top speeds, especially with double-fluted board.

Rotary Shear

Rotary Shear

For the perfect cut every time

When you need to safely remove start-up waste or perform large width changes, count on the Rotary Shear KQ-M from BHS Corrugated to do the job right. It connects directly to the Double Facer and is extremely low-maintenance. This unit is compatible with every standard order change system on the market and is easily integrated into your existing corrugator. This rotary shear reliably handles formats of up to 3,000 g/m2.

Slitter Scorer

Slitter Scorer

There is only one option – precision

The Slitter Scorer from BHS Corrugated gives your corrugator both maximum flexibility and maximum precision. We adapt the configurations based on your required dry end order change speeds. Choose between a version with two scoring stations and one knife station and a version with two scoring stations and two knife stations. Either way, you are guaranteed precise, high-speed scorer and knife positioning. You are also sure to appreciate the integrated grinding device, which resharpens the knives during operation.

Cutoff

Cutoff

Lightweights for heavy grammages

When you compare speed curve values, the Cutoff from BHS Corrugated easily outperforms the competition. The secret is in the ultra-lightweight, directly driven carbon fiber knife bars. What does that mean? Precision cutting – even with extremely short corrugated sheets and even at top speeds. And weight is no problem, either: this unit easily handles grammages of up to 1800 g/m2.

Stacker

Stacker

Neatly stacked – even with short orders

The goal of any corrugated board production operation is to end up with sheets that are even, flawlessly glued and neatly stacked. This is where the Stacker AS-M from BHS Corrugated comes in. The Stacker boasts impressively short cycle times, so it works fast, even with short orders. And stack quality is also guaranteed, thanks to features like the sectionally controllable vacuum belts in the brush brake station and automatic variable drop height adjustment. Whatever size stacking chambers you need, we have a tailored solution just for you.

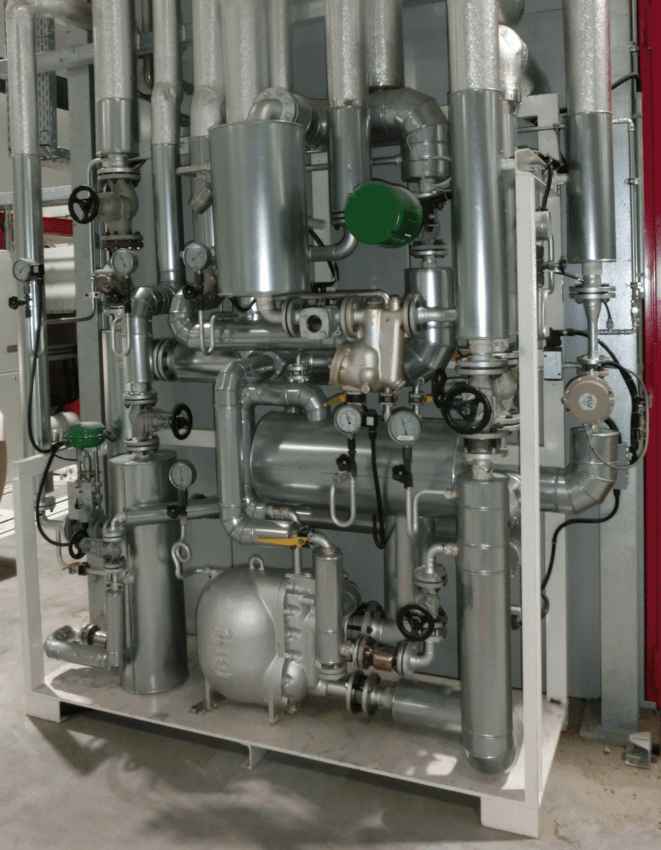

Steam Systems

Steam Systems

Lower energy consumption means higher efficiency

Corrugators have to be heated – and that costs energy. BHS Corrugated set out to find a way to minimize this energy consumption. Now, we are the only machine manufacturer in the world to offer a proprietary closed steam system. It ensures that energy losses are reduced as much as possible and energy consumption is kept to a minimum. We adapt this steam system to work optimally with your corrugator.

Trainings

Your direct way to the corrugator

Contact

BHS Corrugated

Maschinen- und Anlagenbau GmbH

Paul-Engel-Straße 1

92729 Weiherhammer

Hotlines

24-hour Emergency Hotline

+49 9605-919-191

Spare Parts Hotline

+49 9605-919-291 spareparts@bhs-world.com

When you click the play button, content from the YouTube video platform is loaded. Cookies can be saved in the process.

When you click the play button, content from the YouTube video platform is loaded. Cookies can be saved in the process.New video about the Cassette Facer CF-A of BHS Corrugated

How does the Cassette Facer CF-A interact with the FLEX Line?

Based on the industry proven design of the Modul Facer®, the new Cassette Facer CF-A…

An Innovative Start to the Year: BHS Corrugated Introduces the FLEX Line!

Rarely does one experience the beginning of a new era in their own industry. At BHS Corrugated, we have made it our mission to create such…

BHS Corrugated receives HxGN Customer Innovation Award 2023 for iCorr® Maintenance and Operations System (MOS)

We are pleased to announce that our cloud-based maintenance solution, iCorr® MOS (Maintenance and Operations System), has been awarded the HxGN…

Belt meets cassette: The new Cassette Facer CF-A from BHS Corrugated

With the launch of the Cassette Facer CF-A, BHS Corrugated has added another model to its range of single-sided machines. Positioned between the Econo…