Cutoff: High-precision – for the perfect cut

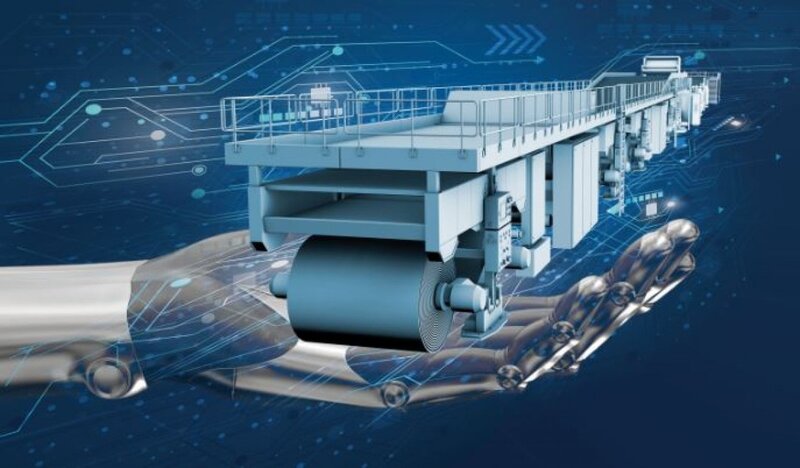

Fast. High-precision. Energy-efficient. Introducing, the Cutoff from BHS Corrugated. Thanks to the use of directly driven and very light carbon fiber knife bars, the Cutoff from BHS Corrugated has the best speed curves in the industry. This allows even very short corrugated sheets to be cut accurately at extremely high speed, while board weight has minimal effects on performance. Cutoffs from BHS Corrugated easily cut sheets as heavy as 1800 g/m² at full speed.

The features at a glance

Working width

Working width

As variable as your requirements

It should be particularly emphasized that the Cutoff, like all other machines from BHS Corrugated, is also available in a working width of up to 3,350 mm. However, the increased working width has no negative influence on speed curves, cutting accuracy or cut quality.

Optionally, the BHS Corrugated Cutoffs can also be configured to discharge production waste at full operating speed, up to 400 m/min.

Integration

Integration

Compact and quickly integrated

Just like all other individual machines from BHS Corrugated, the Cutoff can be quickly and easily integrated into existing corrugators due to its compact design.

Machine safety

Machine safety

The highest standards

Adherence to high standards and compliance with strict regulations are crucial to ensure the safety of users. The quality of the machines also contributes significantly to this. Our products meet these requirements and we do everything we can to ensure that they meet the highest standards. Your safety and satisfaction are our top priority.

intelligent Cut-to-Mark Control (iCMC)

intelligent Cut-to-Mark Control (iCMC)

QR codes on Cutoff for triggering the cutting signal and for closed-loop control.

Camera systems on any number of Cutoff levels upstream and downstream of the Cutoff make it possible to monitor the preprint from above or below with gapless print image recognition. As a result, the system automatically triggers the HQ cut depending on the QR code information.

This eliminates the need for register mark calibration, resulting in significant savings in start-up waste and operator intervention. The reduced space requirement due to the use of standardized QR codes, which can be used for further applications, should also be emphasized.

Furthermore, the system enables closed-loop readjustment of the HQ cut in real time by the deviation from the target position detected by the camera system. This allows the significant reduction of the start-up waste to be enormously increased the cut correction per sheet.

Trainings

Your direct way to the corrugator

Contact

BHS Corrugated

Maschinen- und Anlagenbau GmbH

Paul-Engel-Straße 1

92729 Weiherhammer

Hotlines

24-hour Emergency Hotline

+49 9605-919-191

Spare Parts Hotline

+49 9605-919-291 spareparts@bhs-world.com

When you click the play button, content from the YouTube video platform is loaded. Cookies can be saved in the process.

When you click the play button, content from the YouTube video platform is loaded. Cookies can be saved in the process.Corrugator SPEED Line: high-volume solutions for transregional markets

The SPEED Line from BHS Corrugated features systems that are automated end-to-end, enabling you to achieve production volumes of up to 56,000 m²/hour.…

Sustainability unboxed – Discover the new Box Plant 2025 Season of BHS Corrugated!

With its high recycling rates, the corrugated industry is a pioneer of a modern circular economy. However, sustainable action is not limited to the…

When you click the play button, content from the YouTube video platform is loaded. Cookies can be saved in the process.

When you click the play button, content from the YouTube video platform is loaded. Cookies can be saved in the process.Discover the corrugator WIDTH Line from BHS Corrugated!

The WIDTH Line is a complete corrugator from BHS Corrugated. Amongst others, it is also interesting for paper manufacturers who want to add corrugated…

When you click the play button, content from the YouTube video platform is loaded. Cookies can be saved in the process.

When you click the play button, content from the YouTube video platform is loaded. Cookies can be saved in the process.New video about the Cassette Facer CF-A of BHS Corrugated

How does the Cassette Facer CF-A interact with the FLEX Line?

Based on the industry proven design of the Modul Facer®, the new Cassette Facer CF-A…