Bridge, Bridge Guide and Bridge Brake – for the smooth transport of your corrugated board

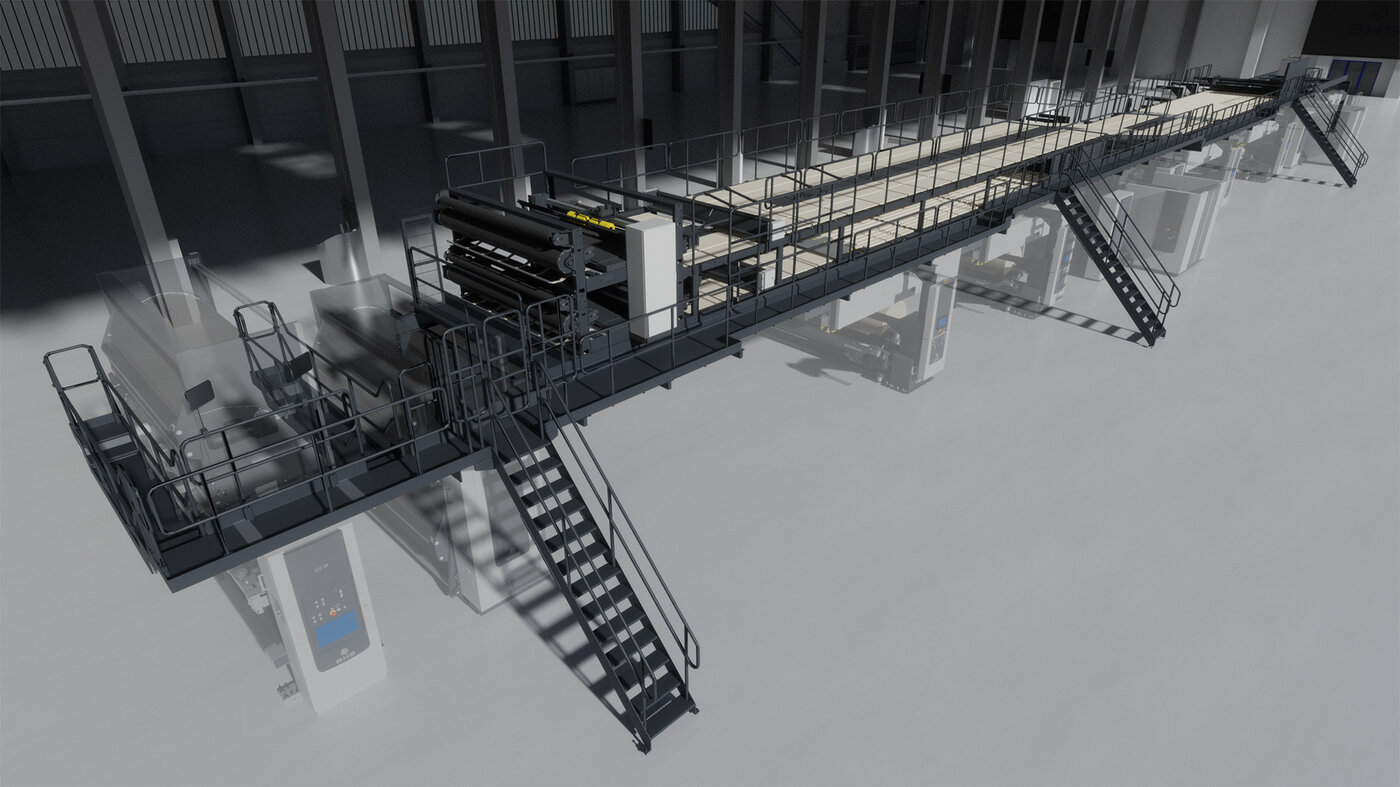

The so-called “bridge” directs the single-faced lengths of corrugated board up to the bridge guide and ultimately to the bridge brake. It can be set up for single, double and triple wall corrugated board. To be able to determine and potentially control the position of the single-faced web at the end of the bridge, BHS Corrugated developed Webtrol, a metering system integrated into the bridge guide.

The features at a glance

Webtrol

Webtrol

Precisely positioned, perfectly prepared

Webtrol guarantees precise positioning of the web towards the center of the corrugator or outside web. With its adjustable brake drum, the BHS Corrugated bridge brake applies precise and constant web tension to provide optimal conditions for high-quality and consistent heating, glue application and subsequent bonding of the corrugated board. The brake resistance can be controlled pneumatically via a brush station with low-wear brushes.

Control dynamics

Control dynamics

High speeds and safe transport

The bridge’s control dynamics are designed for speeds up to 450 m/min; a buffer function is one of the features ensuring consistent web speeds. Manual waste elimination on the bridge facilitates the approach to the corrugator. A high-performance drive and tension system ensures safe transport of the web. A frequency-controlled rotary current motor coupled with the Single Facer is the core element of the drive station.

Operation

Operation

Easy-maintenance and user-friendly

The control console of the bridge is equipped with an integrated touch panel or standalone to monitor the production processes and diagnose any errors or malfunctions. It forms the foundation of the Bridge’s easy-maintenance, user-friendly design. The Zero Defect System (ZDS) guarantees the quick localization of errors and avoids waste by triggering early warnings in case of specified deviations from the standard.

The design of the bridge has received safety approval for all regions worldwide. The individual elements are partially pre-installed at the factory and delivered as modules to be connected at the construction site. This ensures quick assembly.

Machine safety

Machine safety

The highest standards

Adherence to high standards and compliance with strict regulations are crucial to ensure the safety of users. The quality of the machines also contributes significantly to this. Our products meet these requirements and we do everything we can to ensure that they meet the highest standards. Your safety and satisfaction are our top priority.

Trainings

Your direct way to the corrugator

Contact

BHS Corrugated

Maschinen- und Anlagenbau GmbH

Paul-Engel-Straße 1

92729 Weiherhammer

Hotlines

24-hour Emergency Hotline

+49 9605-919-191

Spare Parts Hotline

+49 9605-919-291 spareparts@bhs-world.com

When you click the play button, content from the YouTube video platform is loaded. Cookies can be saved in the process.

When you click the play button, content from the YouTube video platform is loaded. Cookies can be saved in the process.Corrugator SPEED Line: high-volume solutions for transregional markets

The SPEED Line from BHS Corrugated features systems that are automated end-to-end, enabling you to achieve production volumes of up to 56,000 m²/hour.…

Sustainability unboxed – Discover the new Box Plant 2025 Season of BHS Corrugated!

With its high recycling rates, the corrugated industry is a pioneer of a modern circular economy. However, sustainable action is not limited to the…

When you click the play button, content from the YouTube video platform is loaded. Cookies can be saved in the process.

When you click the play button, content from the YouTube video platform is loaded. Cookies can be saved in the process.Discover the corrugator WIDTH Line from BHS Corrugated!

The WIDTH Line is a complete corrugator from BHS Corrugated. Amongst others, it is also interesting for paper manufacturers who want to add corrugated…

When you click the play button, content from the YouTube video platform is loaded. Cookies can be saved in the process.

When you click the play button, content from the YouTube video platform is loaded. Cookies can be saved in the process.New video about the Cassette Facer CF-A of BHS Corrugated

How does the Cassette Facer CF-A interact with the FLEX Line?

Based on the industry proven design of the Modul Facer®, the new Cassette Facer CF-A…