Embrace the future with the Jetliner® Series from BHS Corrugated

Industry-leading Single-pass Inkjet-Systems – individual, digital, and forward-looking

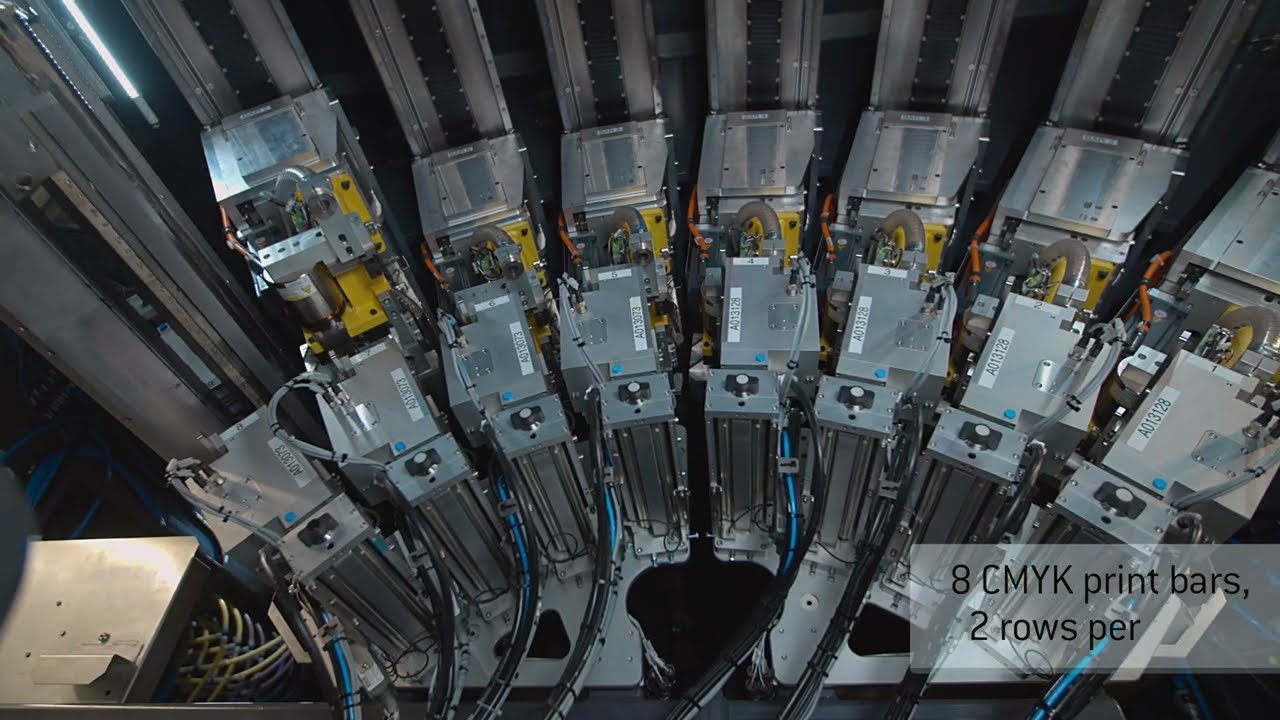

BHS Corrugated Jetliner® is an innovative series of industrial Single-pass Inkjet printing Systems that redefine corrugated board production, offering high automation, advanced technology, and compliance with food packaging regulations.

BHS Corrugated combines industry-proven components with paper handling and mechanical engineering expertise to pave the way for a digital future in corrugated board printing. Their water-based ink system enables versatile applications, including high-speed variable data printing.

Corrugated box plant operators require highly available digital printing solutions that seamlessly integrate into their production processes. The Jetliner® technology from BHS Corrugated offers flexibility and optimization, from raw material consumption to flawless workflow automation, enhancing the efficiency of corrugated box plants.

BHS Corrugated supports customers in leading the way in Single-pass digital Inkjet printing and achieving production digitalization, from design to the final product.

In today's packaging market, challenges faced by Brand owners and Converters drive their actions to stay competitive. Key drivers include time to market, on-demand production, serialization, and versioning. Brands need fast shelf placement, with an on-demand order and production process.

Seasonal versioning has evolved, with many yearly changes now supplemented by special events. These challenges extend to designers and converters. Analog technology falls short in addressing these needs efficiently.

Analog processes on both sides remain time-consuming and resource-intensive, with polymer printing plates, make-ready times, and paper waste as cost drivers. BHS Corrugated Jetliner® Single-pass Inkjet-Systems in box plants enhance equipment effectiveness, cut costs, and reduce waste, aligning with sustainability goals.

To meet customer demands and market trends, brands seek standout packaging, especially as in-home shopping gains popularity. Digital print enables unique QR codes, variable data, and online engagement, enhancing customer experiences and leveraging the possibilities in logistics with intelligent track and trace technology.

Jetliner® Single-pass Inkjet-Systems from BHS Corrugated empower brands and converters to meet market demands creatively and efficiently.

Open House Event by BHS Corrugated Customers experienced the future of corrugated board production at first hand

Technology and innovation are keywords for the corrugated industry of the future. BHS Corrugated is putting both into practice with the Box Plant…

Helmut Kraus, Head of BU Digital & Logistics, has been invited to Podcast of Dan Brunton

In his podcast Group Publisher of The Packaging Portal and Publisher of the International Paper Board Industry (IPBI) Dan Brunton regularly interviews…