BHS Intralogistics: the future of automated intralogistics

More efficient material and logistical processes, a higher level of automation, autonomous solutions. Welcome to Intralogistics 4.0. BHS Intralogistics can help you make that leap into the future. Are you looking to build or upgrade a production site, warehouse or logistics center? From unloading the truck to loading it back up with finished products, we make sure everything stays on track. And on time. Help us turn our motto into reality. Together, we will build... "The future factory."

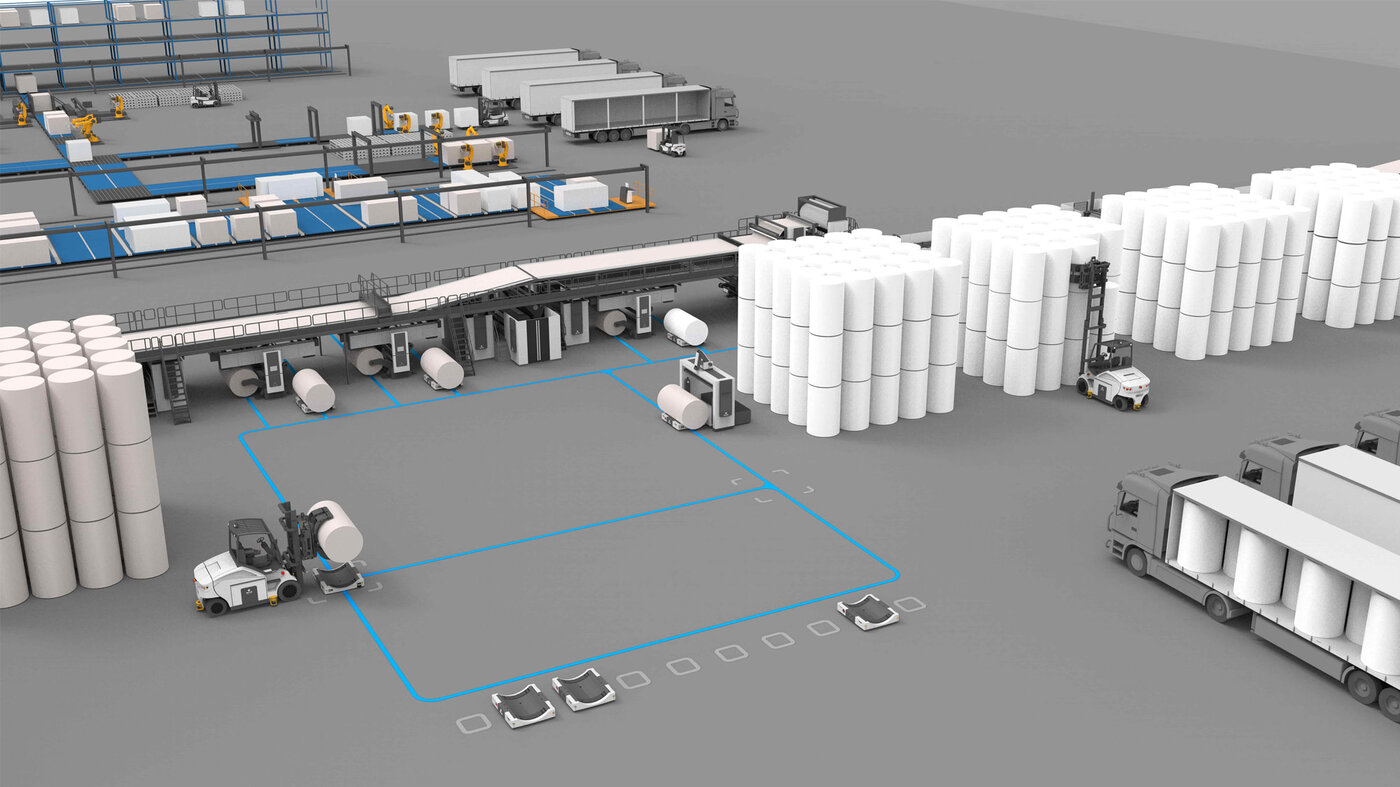

Intelligent movements – autonomous transportation

Solutions from BHS Intralogistics help you redefine the material flow from the loading ramp to the corrugator or Jetliner®. This applies in terms of safety, flexibility and productivity as well as life cycle costs.

Dynamic control of all orders and material movements is handled by the "brain" of the system – the control and management system, in short iCMS. The next innovation step is already in the works with the autonomous iPrep peeling station. Automation provides gentle roll handling while limiting peeling and paper waste to truly damaged layers. This minimizes resource consumption, costs, and the CO2 footprint.

The transfer station as the "hinge" on the way to the corrugator is characterized by impressive load-bearing capacity. Thanks to the flexible design of the transfer positions, it’s able to connect with a wide variety of conveyor systems. Transport to the reel stand is handled by the iShuttle® automated guided vehicles (AGVs) – fast, safe, autonomous and highly available thanks to in-process charging. At the same time, the compact shuttles with a load capacity of 4.4 tons can carry several times the load of any other solution. Minimized process times go hand in hand with 100% correct roll assignment and maximum safety.