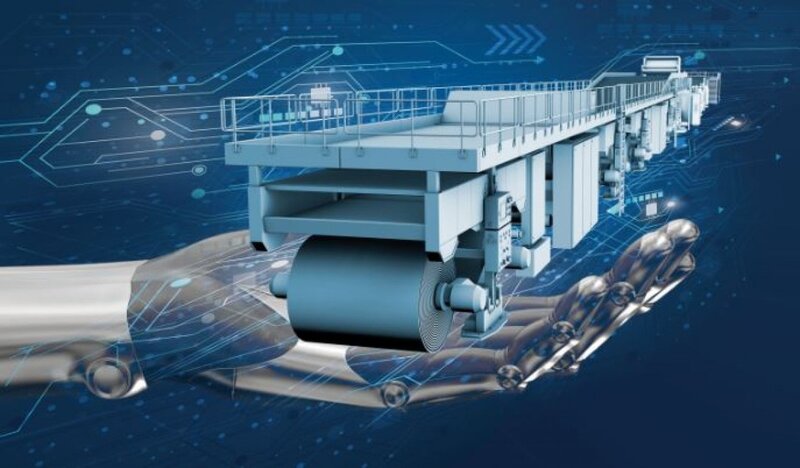

Splicer: constant web tension for smooth continuous operation

BHS Corrugated offers Splicers in different versions with varying technical features, based on the degree of automation and the required production speed of the corrugator. When it comes to paper roll changes, these machines consistently achieve the highest reliability values in the industry. The Splicer functions as a central element for smooth, continuous operation and helps to increase production output – with unmatched splice reliability. At the same time, its flexible design allows for the processing of all commercially available paper qualities from 80 to 440 g/m².

The Splicer is easy to integrate into existing corrugators and comes with a high level of machine safety and high rate of availability guaranteed. It all adds up to a sound investment.

Change with precision: Splicer from BHS Corrugated – the features

TripleControl

TripleControl

Constant tension

TripleControl technology ensures constant web tension under all operating conditions – in real time and with the inclusion of all relevant roll data. We were able to optimize web tension control using unwind brakes, festoon carriages and roll acceleration. This machine meets the highest standards for web tension and the resulting heat transfer from the heating cylinders to the paper. As a result, it achieves splice speeds of up to 500 m/min.

Operation

Operation

Designed for user-friendliness

The easily accessible design, tailored to the needs of the operator, speeds up splice preparation. Another important element in terms of operator convenience is the service diagnosis system. High safety standards are also guaranteed through the use of quality components (F-CPU,) as well as testing and certification in accordance with the German Product Safety Act (GS mark.)

Other technical features

Other technical features

Top performance down to the last detail

- RollBoost: increases splice speed

- PowerBond: increases pressure during the splicing process

- LaunchControl: automated splice preparation; even paper tension across the entire working width

Machine safety

Machine safety

The highest standards

Adherence to high standards and compliance with strict regulations are crucial to ensure the safety of users. The quality of the machines also contributes significantly to this. Our products meet these requirements and we do everything we can to ensure that they meet the highest standards. Your safety and satisfaction are our top priority.

Trainings

Your direct way to the corrugator

Contact

BHS Corrugated

Maschinen- und Anlagenbau GmbH

Paul-Engel-Straße 1

92729 Weiherhammer

Hotlines

24-hour Emergency Hotline

+49 9605-919-191

Spare Parts Hotline

+49 9605-919-291 spareparts@bhs-world.com

When you click the play button, content from the YouTube video platform is loaded. Cookies can be saved in the process.

When you click the play button, content from the YouTube video platform is loaded. Cookies can be saved in the process.New video about the Cassette Facer CF-A of BHS Corrugated

How does the Cassette Facer CF-A interact with the FLEX Line?

Based on the industry proven design of the Modul Facer®, the new Cassette Facer CF-A…

An Innovative Start to the Year: BHS Corrugated Introduces the FLEX Line!

Rarely does one experience the beginning of a new era in their own industry. At BHS Corrugated, we have made it our mission to create such…

BHS Corrugated receives HxGN Customer Innovation Award 2023 for iCorr® Maintenance and Operations System (MOS)

We are pleased to announce that our cloud-based maintenance solution, iCorr® MOS (Maintenance and Operations System), has been awarded the HxGN…

Belt meets cassette: The new Cassette Facer CF-A from BHS Corrugated

With the launch of the Cassette Facer CF-A, BHS Corrugated has added another model to its range of single-sided machines. Positioned between the Econo…