M2P® – From Maintenance to Productivity

All corrugated board manufacturers have their own individual requirements – depending on the size of the business, the expertise of the staff and the particular market environment in which they operate. Production also has to continuously adjust in response to fluctuating production volumes, changing market requirements, and constantly rising cost and competitive pressure. Whatever happens, the productivity of the corrugator plays a decisive role.

Just like the personnel, the maintenance processes that keep the plant running have a direct influence on the output. These factors have to be consistently maintained and improved, so that output factors such as overall corrugator availability, average speed, production quality and waste rate can be optimized long-term. This is the key to increasing the productivity and Overall Equipment Effectiveness (OEE) of your corrugator and stabilizing your manufacturing costs at a low level.

This is precisely the purpose of M2P® productivity and maintenance service for corrugators. “M2P® – From Maintenance to Productivity”: so you can focus on your core business – the production of corrugated board.

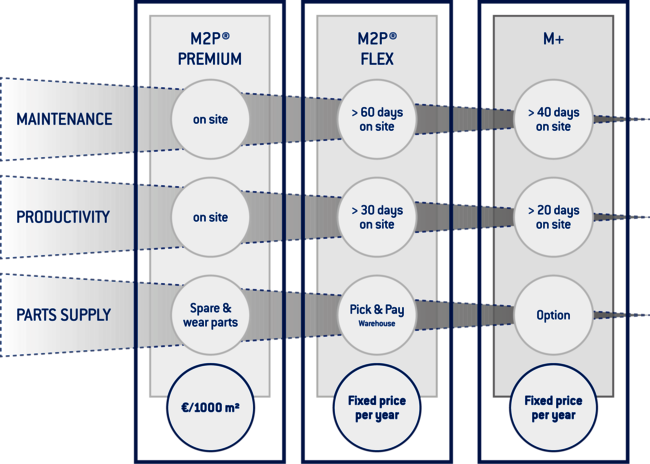

M2P® solution portfolio – always the right scope for your requirements

M2P® from BHS Corrugated is available in different levels based on your particular “make or buy” strategy. Learn more about our M2P® Premium, M2P® Flex and Maintenance Plus (M+) packages.

M2P® Premium

M2P® Premium

Focus on your core business – with 100%

What’s your particular “make-or-buy” strategy? With M2P® – From Maintenance to Productivity – we offer you three levels of targeted support. M2P® Premium, the definite worry-free package, enables measurably higher productivity and better performance. Moreover, you can rely on secured Spare Parts supply – all on a fixed-price basis per 1,000 m² of corrugated board produced.

M2P® Flex

M2P® Flex

Tailored and tiered services, provided jointly

With M2P® Flex, you provide flexible support with maintenance and production optimization on site – the on-site Pick & Pay Spare Parts stock is included.

M+

M+

Our experience as support for your own know-how

M+ lets you order on-site maintenance and productivity as needed – the experts from BHS Corrugated will come to you, bringing along their expertise and experience with corrugators around the world.

“From Maintenance to Productivity” or M2P® is a thoroughly tried and tested approach. It comprises individual modules. These modules combine to form a need-based solution package for you as a corrugator operator to ensure the four decisive factors for the optimally cost-effective operation of your corrugator:

- Consistently high availability

- Maximum performance with regard to average speed and output

- Optimal quality and waste prevention

- Minimal maintenance and operating costs

Click the plus symbol for more information on the modules.

Preventive maintenance

Preventive maintenance

M2P® – Preventive Maintenance Module

With the M2P® Production Optimization Module, you can rely on the following services:

- Performance and optimization of all maintenance services on the corrugator and its periphery – inspection, preventive maintenance and repair – with BHS Corrugated personnel on site and assisted by iCorr® Assist Glasses

- Assessment of the technical condition of the corrugator; assessment, derivation and implementation of recommendations to eliminate limitations

- Performance of a systematic and corrugator-specific maintenance program – preventive and periodic

- Provision of iCorr® Maintenance Cloud (MC) maintenance software from BHS Corrugated for planning, managing, reporting and documenting maintenance activities

- Provision of the iCorr® Operations Support (OS) remote service system from BHS Corrugated with condition monitoring, automatic alarming, data backup and production monitoring

- Personnel training and coaching

Objective: ensure the operating condition, functionality and reliability of your corrugator – as the foundation for sustainable plant availability and productivity.

Production optimization

Production optimization

M2P® – Production Optimization Module

With the M2P® Production Optimization Module, we offer you:

- High overall equipment effectiveness (OEE): Displaying availability, average speed, quality and waste based on the specified production targets

- Regular production and process audits with derivation of proposed solutions

- Consulting and support for the operating personnel (operators) and production management

- Production-optimized machine settings, assisted by iCorr® | OS

- Quality values such as glue application, steam and energy efficiency

- Monitoring for compliance with work safety guidelines

- Regular reporting and status meetings together with you as the plant operator

Objective: High average speed, optimal corrugated board quality and waste prevention – based on optimal production conditions and a perfectly tuned corrugator.

Spare Parts supply

Spare Parts supply

M2P® – Spare Parts Supply Module

With the M2P® Spare Parts Supply Module, we provide:

- Complete Spare Parts supply and logistics, including planning, procurement and transport

- Availability of Spare and Wear Parts on site by setting up a consignment stock

- Provision of iCorr® | MC stock software from BHS Corrugated for planning, managing and documenting the Spare Parts stock

Objective: Spare Parts provision and availability of Spare Parts on-site to prevent downtimes and avoid unnecessarily tying up capital – all while you retain total cost control.

M2P® Service for BHS Intralogistics

M2P®, the productivity and maintenance service for corrugators from BHS Corrugated, is being expanded to include further assets: BHS Intralogistics systems including, for example, BHS iShuttles®. In addition to the corrugator, in M2P® projects BHS Corrugated also takes care of preventive maintenance, productivity optimization and spare parts supply for logistics systems from BHS Intralogistics, thus ensuring consistently high availability and minimum maintenance and operating costs for BHS Intralogistics systems.

M2P® Total Plant Service – for your entire factory

M2P® Total Plant Service is the maintenance package from BHS Corrugated for your entire factory. From the corrugator and its peripherals to the logistical systems and all the way to the downstream processing equipment, BHS Corrugated and our trusted partners will establish an efficient local maintenance network for you. BHS Corrugated coordinates any and all maintenance work in your entire factory and performs it on-site.

The advantage to you: You benefit directly from the experience and competence of BHS Corrugated and have a contact person consistently available on-site.

M2P® – More Productivity

Do you have limited access to qualified and well-trained staff? M2P® (From Maintenance to Productivity) Sheet Feeder supports you with experts in all electrical and mechanical disciplines – full-time and on-site. In addition to our general M2P® offering, it can cover additional assets such as your Digital Printing Unit, BHS Intralogistics systems, UNIVERSAL Fanfold, and peripheral assets.

With M2P® Sheet Feeder, we also take care of availability, average speed, quality, machine settings, and operating costs while reducing waste. Moreover, it contains full spare and wear parts supply.

M2P® Sheet Feeder delivers plannable maintenance and operation costs, and an excellent OEE (Overall Equipment Effectiveness). The currency? A simple formula: € per 1,000 m².

M2P® Operations – Putting 15 years of experience to work

Are you looking for qualified corrugator operators? Recruiting is time-consuming and difficult? Plus, do you need a partner willing to take over responsibility and risks?

M2P® Operations is our offering that aims at high availability, maximum performance, high quality and waste avoidance, reduced operating costs, and considering ESG criteria.

Currently, a team of our technicians is involved full-time in our customers’ operations – as lead operators, operators for the Wet End, Dry End, and Stacker, plus productivity trainers. All we do comes with state-of-the-art standards and tools, and transparent pricing per 1,000 m².