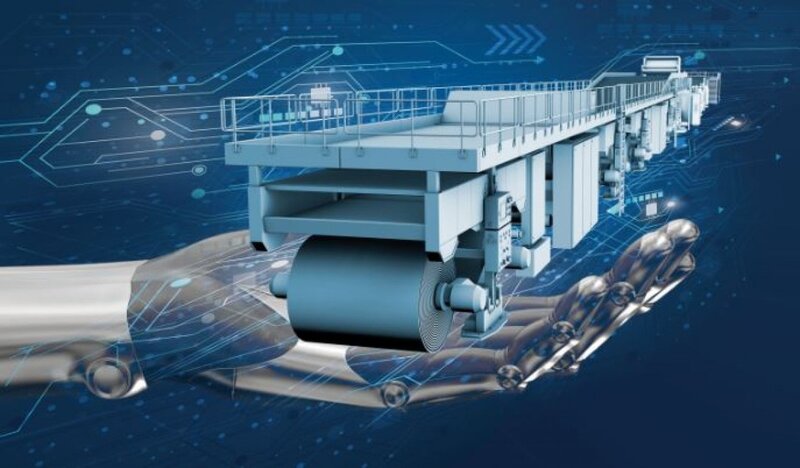

Reel Stand: maximum reliability and precision

These days, corrugators need greater and greater flexibility. Shorter orders and frequent quality changes often limit the corrugator’s productivity and place an increasing burden on operating personnel. When it comes to minimizing speed reductions, the ability to load paper simply and quickly is of great importance. The robust construction of BHS Corrugated’s Reel Stand and the highly precise parallel positioning of paper rolls make for optimum smoothness even at maximum speeds of up to 750 m/min.

The features at a glance

Super smooth running

Super smooth running

Crease-free unwinding

The backlash-free wedge guide between the support arms and the support shaft enables precise adjustment of the arms. This guarantees that the paper roll is unwound without any creases. Hydraulic cylinders lift the paper rolls with maximum reliability and precision. The advantage of the mechanical expansion cones is that they allow the sleeves to be securely fastened. Powerful, ventilated disc brakes ensure adequate braking performance and constant web tension in every speed range – the key requirements for optimal operation.

Roll loading and center alignment

Roll loading and center alignment

Everything is automated

With fully automatic roll loading, the Reel Stand is equipped with sensors to allow work processes to run safely and smoothly. In this version of the Reel Stand, the center of the new paper roll is automatically adjusted to the center of the paper roll which is still in operation. As a result, the paper webs are precisely aligned with one another, and (manual) roll alignment after splicing is no longer necessary. The rest of the roll or sleeve is removed after splicing without any further manual intervention.

Expandibility

Expandibility

Ready for new requirements

The Reel Stand RS-A facilitates entry into the autonomous BHS iMotion® transport system. Along with the BHS iShuttle®, it satisfies the most challenging requirements with regard to the safety and productivity of your corrugator. The Reel Verification System (RVS) ensures that the correct paper roll is used on every Reel Stand.

Advantages:

- Easy integration into existing corrugators

- Allows for loading of extremely narrow rolls

- Time savings thanks to shorter cycle times

- Automatic sleeve ejection for smooth production

Machine safety

Machine safety

The highest standards

Adherence to high standards and compliance with strict regulations are crucial to ensure the safety of users. The quality of the machines also contributes significantly to this. Our products meet these requirements and we do everything we can to ensure that they meet the highest standards. Your safety and satisfaction are our top priority.

Trainings

Your direct way to the corrugator

Contact

BHS Corrugated

Maschinen- und Anlagenbau GmbH

Paul-Engel-Straße 1

92729 Weiherhammer

Hotlines

24-hour Emergency Hotline

+49 9605-919-191

Spare Parts Hotline

+49 9605-919-291 spareparts@bhs-world.com

When you click the play button, content from the YouTube video platform is loaded. Cookies can be saved in the process.

When you click the play button, content from the YouTube video platform is loaded. Cookies can be saved in the process.Corrugator SPEED Line: high-volume solutions for transregional markets

The SPEED Line from BHS Corrugated features systems that are automated end-to-end, enabling you to achieve production volumes of up to 56,000 m²/hour.…

Sustainability unboxed – Discover the new Box Plant 2025 Season of BHS Corrugated!

With its high recycling rates, the corrugated industry is a pioneer of a modern circular economy. However, sustainable action is not limited to the…

When you click the play button, content from the YouTube video platform is loaded. Cookies can be saved in the process.

When you click the play button, content from the YouTube video platform is loaded. Cookies can be saved in the process.Discover the corrugator WIDTH Line from BHS Corrugated!

The WIDTH Line is a complete corrugator from BHS Corrugated. Amongst others, it is also interesting for paper manufacturers who want to add corrugated…

When you click the play button, content from the YouTube video platform is loaded. Cookies can be saved in the process.

When you click the play button, content from the YouTube video platform is loaded. Cookies can be saved in the process.New video about the Cassette Facer CF-A of BHS Corrugated

How does the Cassette Facer CF-A interact with the FLEX Line?

Based on the industry proven design of the Modul Facer®, the new Cassette Facer CF-A…