Technical Corrugator Inspection: a regular check-up to keep you in the know

Cyclical corrugator inspections are the foundation of any sustainable maintenance strategy. That is why regularly scheduled machine audits are crucial when it comes to planning your maintenance and repair in advance.

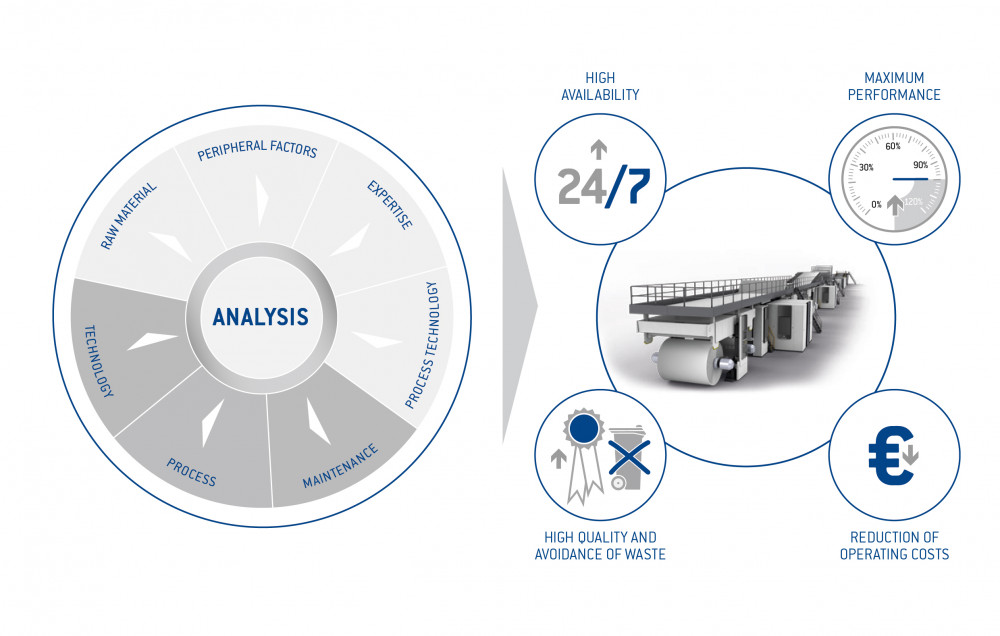

Assessment and optimization

Using detailed checklists, our service technicians analyze the current state of your machines and determine your maintenance and repair requirements. We also diagnose technical limitations and malfunctions. Based on the results of this machine audit, we develop a solution concept to incrementally bring your production performance up to target levels. We also help you plan and schedule the required maintenance work.

Audit and solution concept – in black on white

Upon completion of TCI procedures, you will receive a detailed report covering the results of the machine audit as well as the solution concept. Experienced BHS Corrugated technicians assist you with planning and scheduling maintenance on your corrugator and help you implement the solution concept. This is the key to maintaining the availability of your equipment and helps protect your corrugator investment long-term.

How will you benefit from TCI?

TCI from BHS Corrugated:

- Eliminate and rectify technical limitations and malfunctions in order to reduce downtimes

- Reduce waste, boost availability and speed up production

- Maintenance and inspection work, expertly performed by BHS along with your staff

- Detailed machine audit report and solution concept

- We get your staff involved – coaching & know-how transfer

What else do I need to know?

Implementation

- duration: 6 days (corrugator)

- Staff: 1 electrician and 1 mechanic from BHS Corrugated

- Cost: fixed price upon inquiry

Available for

- complete corrugator

- Wet End and Dry End

- individual machines