The highest possible availability and maximum productivity are the outstanding goals in the operation of corrugators. Regular maintenance is an important element in ensuring the functionality and reliability of equipment. To provide our customers with the best possible protection for this, we offer different forms of maintenance contracts - depending on the share of the tasks they want to take on themselves or entrust to us.

Prevention is at the heart of every maintenance and servicing organization around the corrugator. High availability and low operating costs can only be guaranteed if the defined tasks are carried out according to specifications. We strive to provide extensive automation of recurring maintenance or servicing duties- with the aim of relieving the operator and the plant maintenance team as far as possible. We have also increasingly automated the information and scheduling functions, which provide the operator with important information for planning and executing of maintenance tasks. The newly developed, more visually oriented operating concept - available from autumn 2021 - will simplify this process further.

Everything at hand

It goes without saying, that we provide our customers with all the necessary instructions and information on maintenance and servicing when they commission their machines. In this way, they are comprehensively informed about what needs to be observed when operating their machines and which parts need to be checked in detail. The announcements of the scheduled maintenance dates are shown on the respective operating display - with a direct link to the documentation of the measures to be carried out. This way, customers always have an overview of upcoming tasks. Important: Regular cleaning extends the service life of machines. So please also observe the cleaning instructions that we hand over to you with thestart-up of the machine!

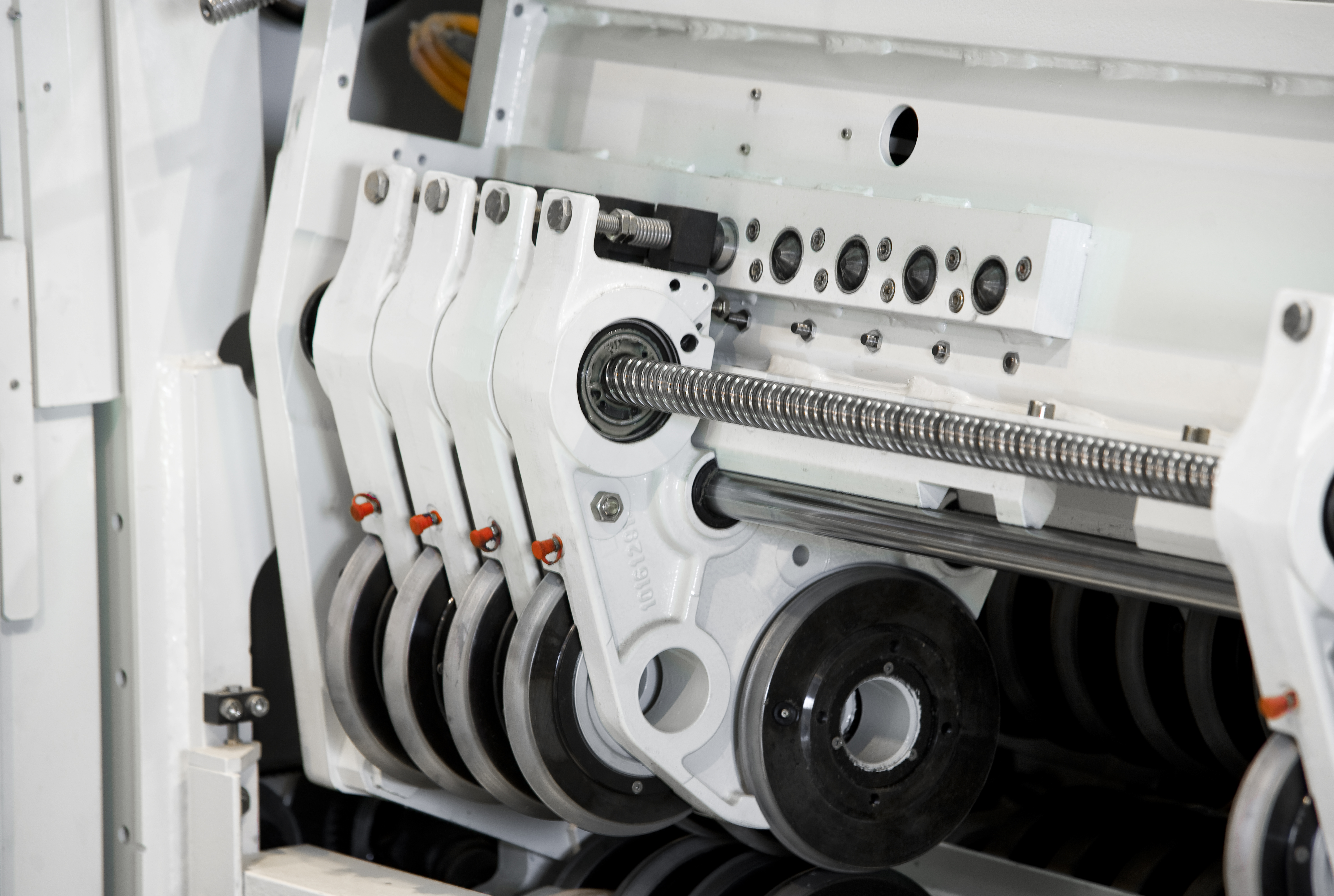

Systems for automated lubrication

One of the regularly recurring and preventive maintenance tasks is the lubrication of permanently stressed machine parts. Of course, we also supply all the necessary documentation for this.

For Slitter Scorers and Cutoffs, customers benefit from our automated lubrication processes. On the Slitter Scorer, the lubricants are transported up from the pump to the elements to be lubricated via hollow-drilled shafts. The control can be carried out in the simplest way via an integrated touch panel.

The oil supply at the Cutoff is similarly "lubricated". Here, too, the circulating lubrication of knife bar gears and bearings can be easily controlled via the oil flow control.

Furthermore, we have also been able to reduce the maintenance efforts on the Stacker AS-M by automating the lubrication of the lifting and safety chains. Here, the lubricant dispenser is directly linked to the machine control. In this way, not only can the amount of maintenance be decreased, but also the wear of the chains can be significantly reduced!