The Jetliner® Series of BHS Corrugated

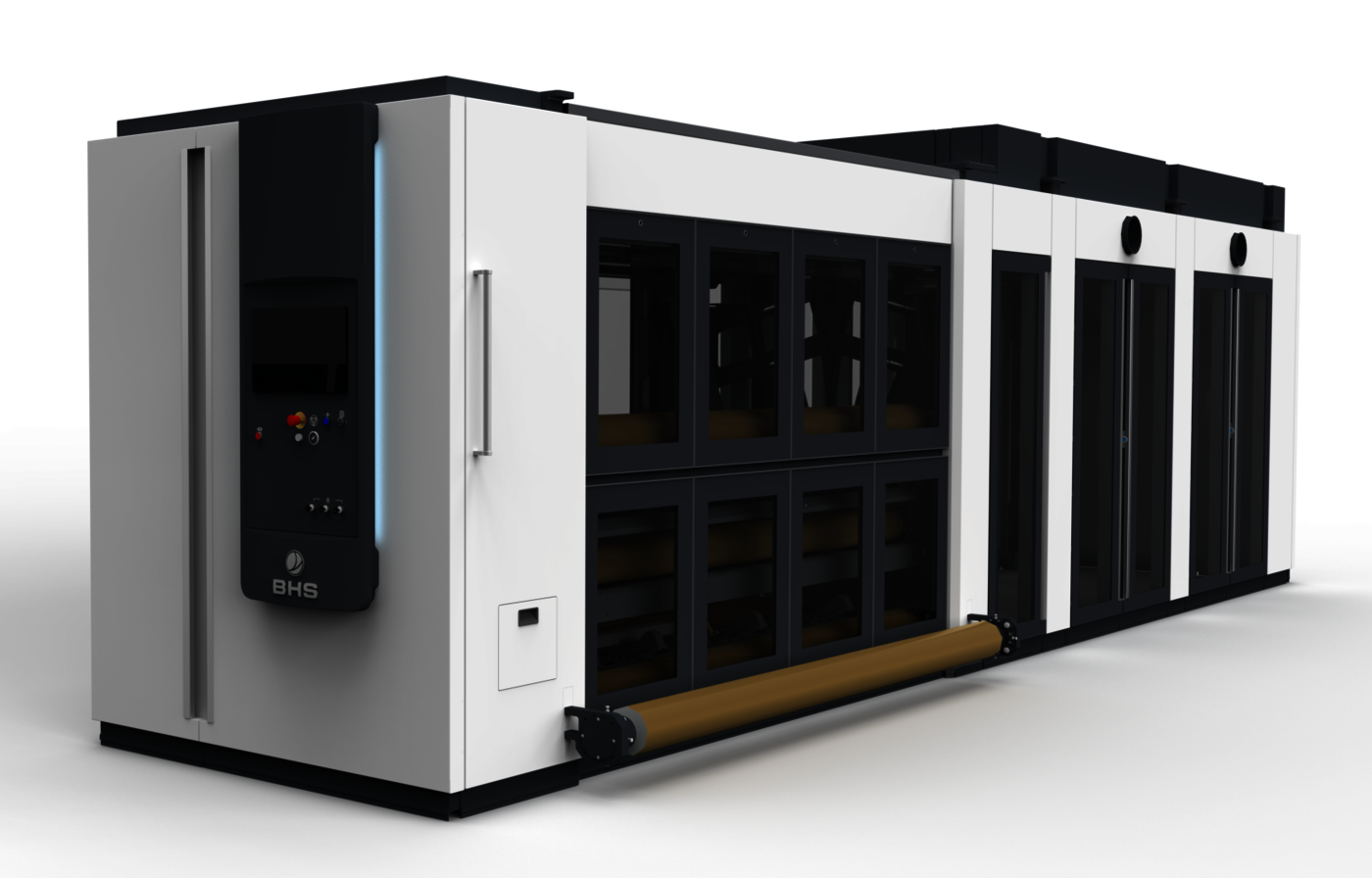

Jetliner® Xceed (XC) - a true industry player

With the Jetliner® Xceed (XC), the era of single-pass inkjet printing has definitely begun. Our system gives you more productivity, flexibility and added value – with less manpower, paper consumption, waste, finishing costs and resources.

The foundation is a holistic technology, application, and support concept. This includes industry-proven and durable piezo print heads, certification of selected and tested inks by our team of experts, and intelligent automation to ensure perfect paper moisture.

Moreover, Jetliner® needs no room air conditioning to protect against dust, heat and humidity thanks to complete encapsulation. Intelligent Uptime & Quality features, in conjunction with Lifecycle Services, support seamless operation and very high availability with virtually no manual intervention. And with flexible operation models – from Roll-Roll to a full inline RSR® process – Jetliner® allows you to tailor your future.

- CMYK Single-pass Inkjet digital printing

- Up to 300 m/min (1,000 ft/min)

- 2,800 mm (110 '') working width

- Roll-to-roll printing process

- Innovative RSR® inline printing process technology

- Industry-proven printheads

- Water-based ink system (compliant with EuPIA, Swiss Ordinance, and Nestle guidelines)

- Primer

- Analog varnish

- Digital varnish

Jetliner® Monochrome (MCP) - your code for a growing market

Corrugated board is developing in leaps and bounds into a data carrier – for promoting brand content as well as for documenting the value chain via dynamic QR code.

With the Jetliner® Monochrome (MCP) single-pass print system, you can tap into this growing market and at the same time already comply with the EU Packaging Waste Directive. In both new and existing corrugators, an almost unlimited variety of monochrome printing applications are open to you. Thanks to its modular design, the Jetliner® can also cope with tight spaces. Print at corrugator speeds and utilization of the full 2.800 mm working width ensure powerful productivity.

Generally speaking, you benefit from the technology and development of the Jetliner® Xceed (XC). With its holistic concept, it enables extremely precise, low-waste, and largely autonomous printing processes. Plus, minimized printhead costs throughout the entire lifecycle.

- One color (Black) Single-pass Inkjet digital printing

- Up to 400 m/min (1,300 ft/min)

- 2,800 mm (110 '') working width

- Innovative RSR® inline printing process technology

- Industry-proven printheads

- Water-based ink system (compliant with EuPIA, Swiss Ordinance, and Nestle guidelines)

Printer Control Center (PCC) - Printing in a different league

One of the key questions of single-pass inkjet printing for corrugated is: How can you print a variety of different orders in different volumes on one web?

The Printer Control Center (PCC) facilitates batch printing with maximum operational performance. Order by order, it automatically manages manifold parameters – from the color profile to the shrink factor to the dryer settings, to name just three of many aspects that impact the efficiency of your printing process and the quality of the product. Always with the knowledge of each paper supplier, each paper grade, and each grammage in mind. That’s intelligent process control applied in practice.

At the same time, single-pass inkjet printing is also about optimizing orders – with the aim of utilizing every square meter of paper as far as possible. With its standardized interfaces, the PCC enables an error-free marriage between the digital print sheet and your scheduling system. Moreover, it integrates systems such as the camera inspection or the Raster Image Processor (RIP): Just everything that makes a holistic solution.

Open House Event by BHS Corrugated Customers experienced the future of corrugated board production at first hand

Technology and innovation are keywords for the corrugated industry of the future. BHS Corrugated is putting both into practice with the Box Plant…

Helmut Kraus, Head of BU Digital & Logistics, has been invited to Podcast of Dan Brunton

In his podcast Group Publisher of The Packaging Portal and Publisher of the International Paper Board Industry (IPBI) Dan Brunton regularly interviews…